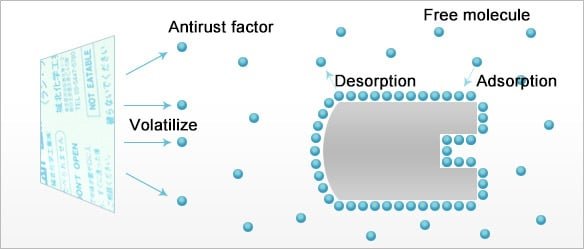

The development of the vapor phase inhibitor application technology has an important traction effect on the basic research and application development of the vapor phase inhibitor industry.

The application technology of VCI mainly reflects in the development and application of gas-phase antirust products with different carrier types. Practical application through half of century, now, there are many kinds of antirust products in the market.

1.The film and bag with antirust use polymer materials as a carrier. VCI is implanted in it by a reasonably feasible blown film technology process. The polymer material includes polyolefin PP, PE, EPE and so on. The application of PE is the most extensive among them. VCI sublimates steadily from the carrier to the surface of the metal forming a dielectric isolation protective layer.

2.The paper with antirust dissolves VCI in the solvent forming the special medicinal solution, made by coating or spraying. The basic material of the carrier is mainly the special fiber antirust base paper, classified by the veins of the paper, there are two kinds, plain weave, and wrinkle.

3.Antirust liquids are mainly divided into antirust oils and antirust liquids. As the name implies, their differences are mainly reflected in different carriers, which are oil-based and water-based. Generally speaking, layers with the oil-based protective film are relatively stable, but they are not as environmentally friendly as water-based one

4.Anti-rust powders transform VCI to the powders and mixed with carrier additives of certain special powder in a certain proportion to obtain the optimal VCI corrosion inhibition effect, such as an anti-caking agent to prevent agglomeration of powder, and wetting agent for wet use.

5.Granules with antirust transform the VCI powder into granules and then mixed with a mineral desiccant with an equivalent particle size to make a multi-effect rust-proof desiccant. This is the most widely used method of rust-proof granules currently.

- 6.Tablets with antirust add an appropriate amount of excipients into VCI powder to make tablet-like VCI flakes by mechanical compression. The counterparts in German impregnate the anti-rust liquid into the fiberboard by dipping. Then, the plate was cut into small pieces by die-cutting. Rustoper add VCI into the new copolymer and develop the VCIrus-713 product by injection molding. This is a small flat cube, SRPP also classifies them as rust-proof tablets.

- 7.Software products with antirust are soft but have certain plasticity and toughness. They are especially suitable for rust prevention of slender and small-diameter pipes and other internal cavities. Rust-resistant plastic pipes have also come out abroad. Rust-resistant ropes are similar products with Rustoper. Compared with rust-resistant plastic pipes, rust-resistant ropes are more environmentally friendly and can be directly degraded.

- 8.In most cases, rust-proof blocks refer to the rust-proof emanant bodies. At present, most of the rust-proof emanant bodies on the market are anti-rust powder or granules, which are placed in a packaging container with a breathable surface. Stick the packaging container to a metal surface when using it. The Rustoper anti-rust emanant bodies use a unique approach, adopt the same production method of the above-mentioned sixth anti-rust sheet.

- 9.Complex material with antirust obtain the performance properties of other materials, such as toughening, moisture resistance, abrasion resistance, cushioning, antistatic, radiation protection, etc., relevant materials can be compounded on the rust-resistant carrier substrate to make composite type Rust products, Rustoper-Shenyang SINO-VCI has more complete materials of vapor phase antirust composite materials, including the five categories of VCIrus-748A / B / C / D / E, it provides a rich choice for the market and meets the customers’ requirements of diverse and personalized anti-rust.

- 10.Other products with antirust, such as anti-rust sponge, anti-rust coating, anti-rust non-woven fabric, etc.