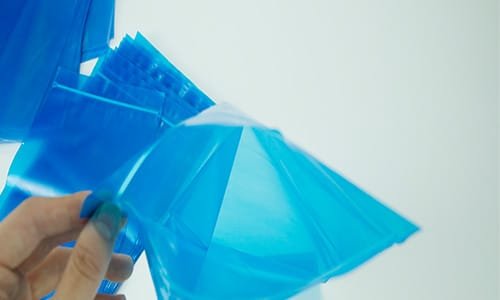

Anti-rust bags are widely used in the export of marine packaging for metal parts. So, what are the process characteristics of VCI gas-phase anti-rust bags?

1.Engineers with ten years of experience in the industry to ensure that the thickness of the blown film is uniform and the welding of the anti-rust bag is firm.

- 2.From raw material procurement, production to shipment, real-time monitoring of each production link, and quality both are guaranteed.

- 3.Using special functional additives, anti-rust cycle time up to 24 months.

- 4.VCI anti-rust bag is independently developed and can be customized according to customer needs. The product size, thickness and style can be customized to meet the anti-rust packaging of different products.

- 5.Anti-rust has been serving various large auto parts companies and can provide various anti-rust packaging solutions.

- 6.Our company has been focusing on the R & D and production of VCI anti-rust bags for 15 years. It has its own 4000-square-meter production workshop. It has sufficient inventory and 0 intermediate links to save costs for your business.

- 7.We can provide a full range of intimate services from pre-sale technical consultation to sample design during sales and regular return visits after sales.