What are the requirements of anti-rust packaging technology:

1. Determine the anti-rust packaging grade and pack it according to the grade requirements to ensure that the parts and assembly will not produce rust within the rust prevention period.

2. The parts and assembly before anti-rust packaging should be clean, free from rust, burrs, and bumps. The anti-rust packaging operation process should be continuous. If the spare parts that cannot be installed are interrupted, the No. 2 gas-phase anti-rust paper should be taken for temporary anti-rust treatment.

- 3. Anti-rust packaging operations should be carried out in a clean, dry environment with a small change in temperature. The parts and assemblies that have been processed with anti-rust packaging have been stored in the warehouse of the anti-rust station for more than 3 months. The quality of the anti-rust must be checked at random.

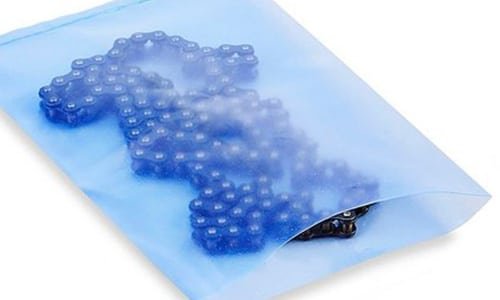

- 4. For example, when the assembly of the metal assembly is packed with ferrous metal gas-phase anti-rust paper, the non-ferrous metal parts must be coated with anti-rust oil before packaging.

5. When parts and assemblies after applying the anti-rust agent need to be covered with inner packaging materials or fillers in boxes, neutral, dry, and clean packaging materials should be used.

- 6. When nailing a wooden box, it should be noted that the parts in the box must not move, so as not to damage the rust-proof products. When nailing the box, the nail head, and nail tip should not be exposed on the surface of the box plate, and the steel nails should not be bent or nailed at the contact point of the box plate frame.

7. To prevent skin irritation caused by anti-rust materials and prevent hand sweat from corroding metals, operators apply some petroleum jelly on their hands or wear gloves.