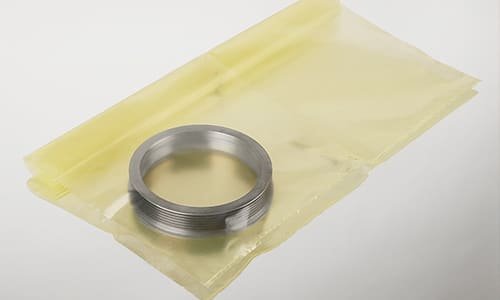

The anti-rust bag is a kind of anti-rust packaging material made of polyethylene material as a carrier, mixed with gas-phase anti-rust agent and other additives, and processed by special extrusion equipment. Belongs to a new type of anti-rust packaging materials, especially suitable for long-term storage of metal products and anti-rust protection of shipping.

What are the requirements for the operation of shipping anti-rust bags and export anti-rust bags?

1. Before packaging, confirm that the packaged object is not rusted, clean, or attached to other corrosive chemicals.

- 2. When packaging, the temperature of the packaged object must be consistent with the space temperature.

- 3. When used for large equipment packaging, large box lining packaging, and intensive product packaging, it is recommended to choose a variety of VCI materials for use together, such as anti-rust paper, anti-rust bag, and anti-rust powder.

- 4. Gloves must be worn during the entire operation to avoid product rust caused by hand sweats.

- 5. The most important thing is to use the products of regular anti-rust bag manufacturers. The anti-rust bag product market is very responsible, to avoid the mixing of miscellaneous materials into the anti-rust packaging, which will cause secondary damage to the anti-rust products.

Anti-rust Material Co., Ltd. was established in 2005.

It is a production-oriented enterprise integrating production, research and development, and sales.

It mainly deals with anti-rust products such as gas-phase anti-rust bags, gas-phase anti-rust films, and gas-phase anti-rust papers.

Mainly used in the automobile manufacturing industry, electromechanical parts manufacturing industry, large equipment manufacturing industry and aviation, shipbuilding, military industry, and other industries, has more than 15 years of industry experience in the field of rust prevention, is committed to solving rust packaging solutions for customer systems.