The full name of VCI is a Vapor Phase inhibitor, which is a kind of vapor phase rust inhibitor, also often called a vapor phase corrosion inhibitor. VCI anti-rust film adopts vapor phase rust prevention technology.

VCI is a kind of active anti-rust material different from anti-rust oil and paint. It can protect metal and other materials anytime and anywhere in the permitted environment.

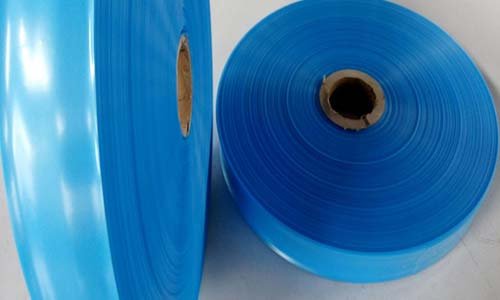

Good quality VCI anti-corrosion film in the production process should be uniform in thickness, light transmittance is slightly lower than ordinary polyethylene film, the overall feel is smooth, grainy, and excellent tensile properties.

VCI is more environmentally friendly than traditional rust-preventive oils. It does not need to be cleaned before use. In addition, the cost is more suitable for business needs. Therefore, the characteristics and application range of VCI anti-rust film are introduced in detail.

VCI film is a new generation of innovative high-tech products made by applying VCI VCI technology to polymer materials.

It has excellent vapor phase and contact rust prevention performance, and the rust prevention period can be as long as 2 years. The transparent feature allows workers to directly observe the state of the package.

It is safe and convenient to use, relatively clean, fully recyclable, strong in weldability, good printability, and waterproof and moisture-proof. The anti-rust effect is very good, and it overcomes the shortcomings of insufficient protection of products by traditional methods.

It is especially suitable for anti-rust packaging in the processing, storage, and transportation of metal parts in military, machinery, auto parts, electrical, hardware, and other industries.

It saves labor, time, and cost, and the comprehensive economic benefits are significant. Often used in various hardware and powder metallurgy;

In addition to automobile and motorcycle parts, there are bearings, clutches, motors, and valves;

Mechanical parts, medical machinery, precision instruments, iron castings, aviation parts;

Various electric tools, measuring tools, cutting tools;

carbon steel, alloy steel, cast iron, steel phosphating, steel nitriding, steel blue, powder metallurgy, oriented silicon steel, non-oriented silicon steel, etc.