Many problems will be encountered in the process of purchasing gas-phase anti-rust bags and using gas-phase anti-rust bags. How much do you know about the common problems of VCI gas-phase anti-rust bags?

VCI gas-phase anti-rust bags are widely used in auto parts, electromechanical products, precision bearings, large machine tool equipment, electronic and electrical equipment manufacturing, high-speed rail car components and military products.

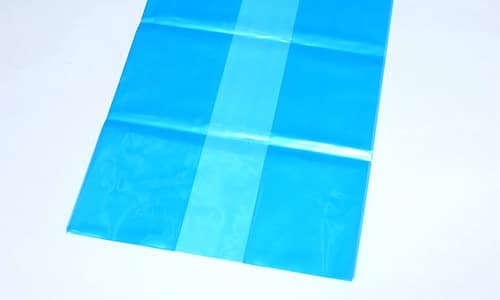

VCI gas-phase anti-rust bags package various regular or irregular products into a whole, so that the goods can be protected by anti-rust, prevent scratches, bruises, waterproof and moisture-proof, anti-ash layer, reduce the rust caused by poor anti-rust Economic losses.

VCI gas-phase anti-rust bag is one of the advanced anti-rust packaging methods on the international market. During the entire operation process, gloves must be worn to prevent hand sweat from causing product rust.

Do not expose the gas-phase anti-rust bag for a long time before packaging. It should be sealed as soon as possible after packaging. It can be sealed with heat seal, tape, cable tie, etc., and the unused anti-rust bag should be resealed and stored.

At present, the gas-phase anti-rust bags in the market have been produced in many places in China. Our anti-rust bags have focused on R & D and production of VCI gas-phase anti-rust bags for 15 years. We can customize gas-phase anti-rust bags of various sizes and thickness according to customer needs.