Different positions of containers on the cargo ship

The location of the container on the cargo ship may be one of the most difficult variables to control. We can hardly predict or control, but it will have a very important impact on the environment of the entire transportation process.

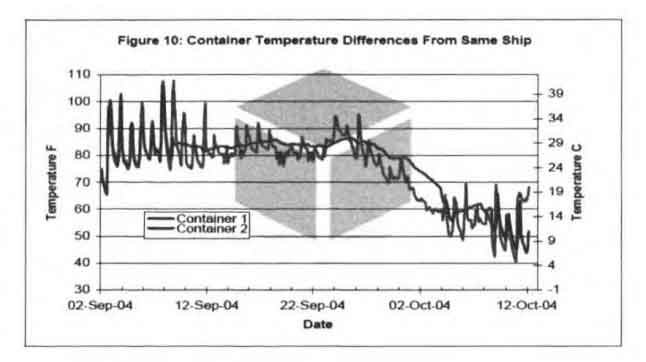

By measuring multiple containers transported on the same ship, we found that there is a temperature difference between the containers in different locations on the ship.

As shown in Figure 1, the temperature of Container No. 2 gradually changed during the entire voyage, while Container No. 1 showed temperature fluctuations.

Container No. 1 is loaded on the deck of a cargo ship. The light directly affects the temperature change of the container, while Container No. 2 is covered by other containers, which naturally controls the temperature change.

Image 1

Different positions of the cargo in the container

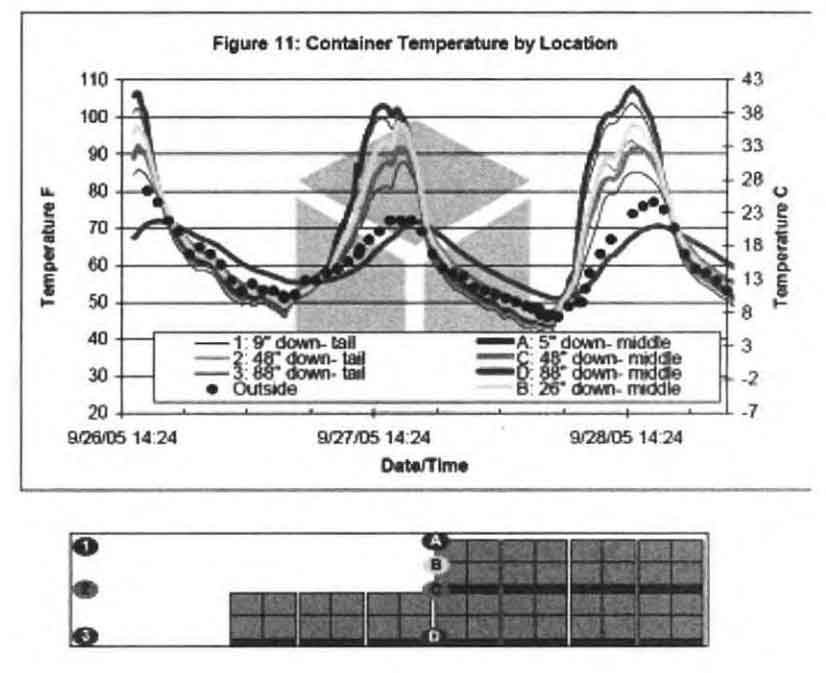

This is a controlled variable test monitored by a temperature recorder in a container that is not completely filled with cargo. Figure 2 details the temperature changes recorded by the recorders at different locations in the container in three days.

In the afternoon, the temperature at the top of the container was 35°C (19°C) higher than at the bottom.

This phenomenon can be explained by the fact that the top usually receives more direct light than the sidewalls of the container, so the top is usually the hottest part of the container. This can explain why corroded parts sometimes appear on high pallets.

Image 2

Different materials of the packaging container

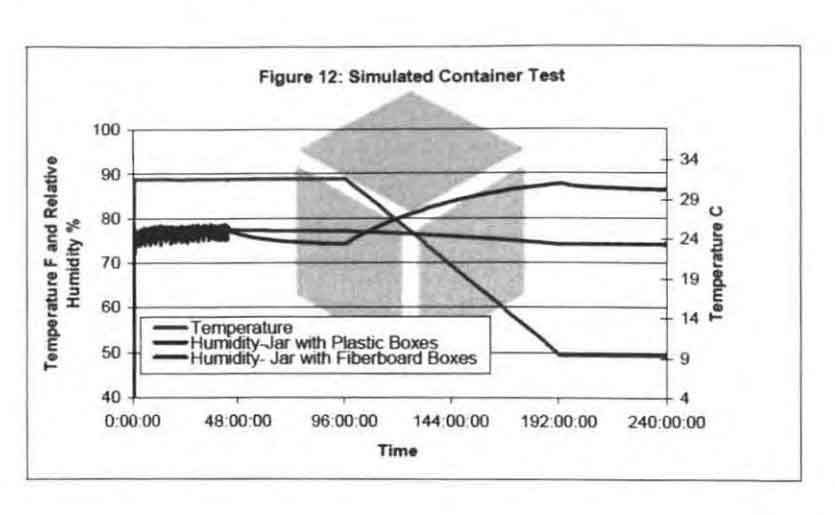

Permeable materials involved in packaging, such as corrugated boxes, paper, dunnage, etc., can slowly absorb moisture from the air, effectively reducing condensation during ocean transportation, especially at night.

As shown in Figure 3, the relative humidity in the fiberboard box is lower than that in the plastic box. The information reveals why many auto parts manufacturers choose to change from corrugated boxes to recyclable plastic pallets, condensation will occur in the packaging and cause corrosion problems on metal parts.

Image 3

Quote-[1] Xing Xiangxu, Fernando Longinotti. The application of vapor phase rust prevention technology in sea transportation of auto parts[C]//The Second Annual Conference of Automobile Anti-corrosion and Aging Branch of Chinese Society of Automotive Engineering. 2016